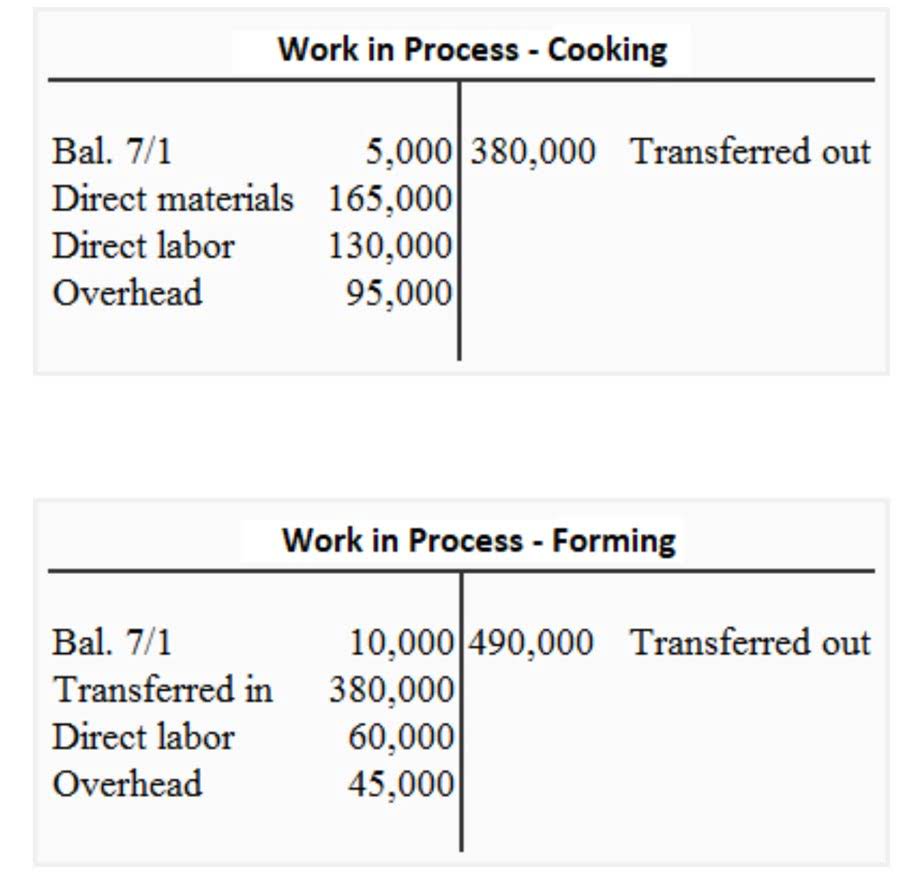

In this section, we will delve into the concept of Conversion Cost Variance and explore how it can be measured and analyzed. Conversion costs refer to the expenses incurred during the transformation of raw materials into finished goods. Conversion cost, as the name implies, is the total cost that a manufacturing entity incurs to transform or convert its direct materials into salable or finished product. Typically, it is equal to the sum of entity’s total direct labor cost and total manufacturing overhead cost. In this section, we will delve into the concept of the conversion cost ratio and its significance in cost accounting and management. The conversion cost ratio measures the proportion of conversion costs to the total manufacturing cost, providing valuable insights into the efficiency and cost-effectiveness of the production process.

Conversion Costs

- Remember, the pursuit of cost-effective conversion doesn’t compromise product excellence—it ensures sustainable growth and customer satisfaction.

- To speed up the production process, they rented an assembly plant for ₹1,50,000/Month.

- Analyzing conversion cost variance involves investigating the reasons behind the variance and identifying the specific cost components that contributed to it.

- The raw materials required for the product are transformed through specific processes, and finally, products are developed for sale in the market.

- To plan the production budget, the conversion cost per unit can be multiplied by the expected number of units to be produced in the future.

In summary, understanding the components of conversion cost empowers businesses to optimize their production processes, manage Insurance Accounting expenses effectively, and make informed decisions. By considering direct labor, direct materials, overhead, depreciation, quality control, and the conversion cost formula, organizations can enhance their cost control strategies and drive profitability. Remember that these components interact dynamically, and a holistic approach is essential for accurate conversion cost analysis. The 1,200 ending work in process units are only 35% complete with regard to conversion costs and represent 420 (1,200 × 35%) equivalent units.

Difference between Conversion Cost and Prime Cost

For the final assembly of cars, they rented heavy-duty machinery for ₹80,000 and paid ₹50,000 as the electricity bill. If it is not, such as just one or two conversions from 1,000 clicks, consider pausing the keyword. You see which of your campaigns have the lowest cost per conversion, preferably compared to high values for those conversions, and focus your efforts and budget on them. Remember that you can define conversion however you want, such as the number of sales and number of operating leverage dol formula + calculator signups for your email list. The following are some of the most commonly used conversion metrics when assessing conversion cost. Each has its own example of how you would net sales assess conversions with your given definition for the conversions.

Unit Converter

The total of direct labor costs and manufacturing overhead costs gives you the conversion cost for a specific period (e.g., a month or a quarter). Rather, such expenses are considered as indirect labor which goes to the entity’s total manufacturing overhead cost (discussed later in this article). Examples of such expenses include the salaries of production supervisor and factory watchman etc. Conversion Cost Variance is a crucial metric for cost accounting and management.

How to Use the Conversion Cost Information for Decision Making and Management?

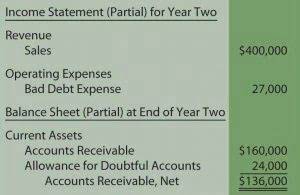

Conversion costs are calculated in order to know the cost per unit, which assists the company in deciding a price for the product. A periodical review of the firm’s prime cost is crucial to ensure the efficiency of its manufacturing process. The computational responsibility lies with the factory manager who collects the relevant data, calculates the prime cost figure for the period and reports the same to operations manager for review. This indicates that 25% of the total manufacturing cost is attributed to conversion costs. A positive variance indicates that the actual conversion costs exceeded the budgeted costs, while a negative variance suggests that the actual costs were lower than the budgeted costs.

- The inventory valuation is the cost of the goods that are not sold and remain in the ending inventory, and it is reported as a current asset in the balance sheet.

- Some common examples are insurance, building maintenance, machine breakup, and taxes on equipment or machining.

- In the Peep-making process, the direct materials of sugar, corn syrup, gelatin, color, and packaging materials are added at the beginning of steps 1, 2, and 5.

- Compare the conversion cost per unit with the previous periods, the industry average, or the target cost to evaluate the performance and efficiency of the production process.

- As can be seen, labor is the cost that mainly determines the transformation or conversion process, then from here on there must be costs of a similar nature or of a similar impact.

Understanding Direct Conversion Costs

Direct labor costs are the wages and benefits paid to the workers who directly work on the product. Manufacturing overhead costs are the indirect costs that support the conversion cost formula production process, such as utilities, rent, depreciation, maintenance, etc. These costs include wages, salaries, and benefits paid to workers directly involved in the production process. For instance, assembly line workers, machine operators, and quality control personnel contribute to the conversion process. Their time and expertise are essential for turning raw materials into usable products.

- Assume that there was no work in process inventory at the beginning and at the end of the accounting period.

- These examples illustrate how the conversion cost formula and per unit cost can be applied to different scenarios.

- The following are some of the most commonly used conversion metrics when assessing conversion cost.

- They offer insights into the efficiency of manufacturing operations and potential areas for cost reduction.

- Conversion costs are calculated in order to know the cost per unit, which assists the company in deciding a price for the product.

- Thus, each cost concept provides a somewhat different view of the costs incurred to create products.

This means that the toy company spends $10 on direct labor and manufacturing overhead for each doll it produces. How to use conversion cost for cost accounting purposes, such as assigning costs to products, inventory valuation, and variance analysis. Manufacturing cost is the cost that company spends to support the production process but they cannot allocate to each product. They are the indirect cost that incurs to support the manufacturing, but it is very challenging to apply the cost to each production unit. In summary, managing and reducing conversion costs requires a holistic approach, combining process optimization, strategic partnerships, employee engagement, and technological advancements.

Najnowsze komentarze